AQUAVISOR® TELEMETRY

Service optimization and cost reduction of decentralized sewage treatment plants by remote monitoring and remote operation

Aquavisor® is a scalable telemetry platform that can be adopted to your particular requirements and IT infrastructure.

- Plant monitoring via 2G/4G or LoRa®/Sigfox®

- Full remote control

- Access via web browser

- Scalable from 1 - ∞ plants

- Error notification via e-mail

- Different access levels to the plant data

Why use the Aquavisor® Telemetry System?

- With the clear-text error messages you know what you can expect on-site

- Remote control allows you to solve problems without leaving your office

- Service planning and digital maps helps you to optimize your service trips

- Digital service reports enable your auto-matic invoicing

- Plant and customer database with photo and GPS coordinates will help you to find the plant

- Telemetry facilitates various operator models (BOT, BOOT,…)

- Telemetry provides evidence to water authorities of proper plant functioning

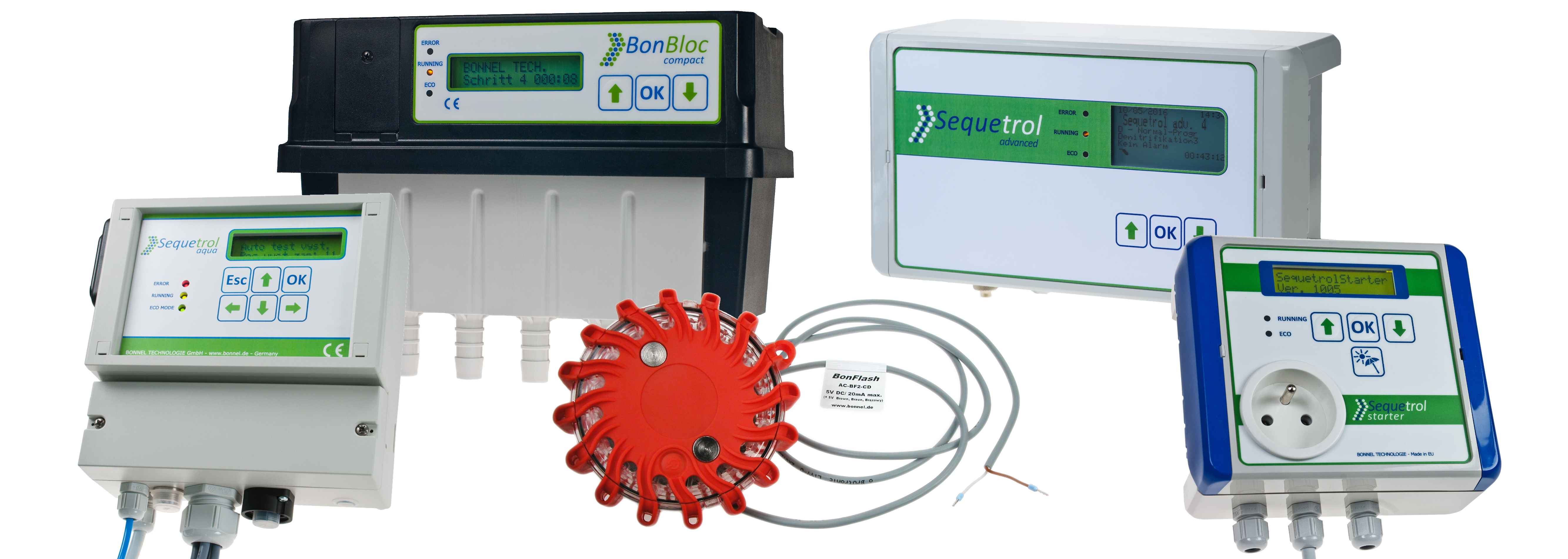

Basic functions

Remote monitoring

Plants are monitored remotely via 2G networks. On request, 4G and LoRa®/Sigfox® are available, as well.

Alarms and events can be forwarded by mail to the service company and/or plant owner.

Data storage

All data will be stored in SQL databases on a server. This can be either your server, a BONNEL server or cloud servers.

Stored data contains alarms and events, as well as all plant data (e.g. address, GPS coordinates), cus-tomer contact data and service company data.

Data access

You can view and modify the data via the Aquavi-sor® webpages, that you can access with any brows-er from your PC, tablet or mobile phone. Different user levels for the plant owner, the service compa-ny and the portal owner are available.

Service reports

Your service reports can be stored into the data-base as pdf files. Like this, your service history re-mains transparent and you can easily review it.

Remote control

The plant can be fully remote-controlled. You can change all parameters and acknowledge alarms. Perform manual operation and even monitor the pressure or current values during these tests.

Firmware and software updates

Firmware and software can be updated remotely, either on particular plants or on all plants. Like this you can keep all control units up-to-date.

Functions on request

Extended Service Reporting

On request, digital service reports can be added. The reports are designed for your fast and simple completion on-site using prefilled fields, combo-boxes and similar. The design and scope of the re-port can be agreed individually.

Connection to your ERP/CRM/accounting system

An interface to your ERP can be created, to synchro-nize data between the Aquavisor® telemetry data-base and your ERP system. This empowers you to transfer various data, as customer data and data about performed works, worktimes and distances to other systems. This data is vital for automatic in-voicing systems, which can generate relevant savings at the administrative costs for you.

Reporting functions

Reporting can be necessary for different legal re-quirements. In some countries, subsidies for plants will only be granted, if periodic reports about the operation of the plant are provided. Also operator models like Public Private Partnership (PPP) mostly require reporting.

But reporting can also help you to analyze processes and products by means of statistical approaches like SPC.

Automatic service-trip planning & optimization

According to planned service dates, incoming alarm messages, and average times for regular services and troubleshooting, the Aquavisor® telemetry sys-tem can be extended on request to suggest or to optimize service trips. You can save administrative costs and use the shift time of your servicemen to full potential.

ČESKY

ČESKY  DEUTSCH

DEUTSCH  ENGLISH

ENGLISH